Unrivalled Strength-to-Weight

The Ultimate in Composite Engineering

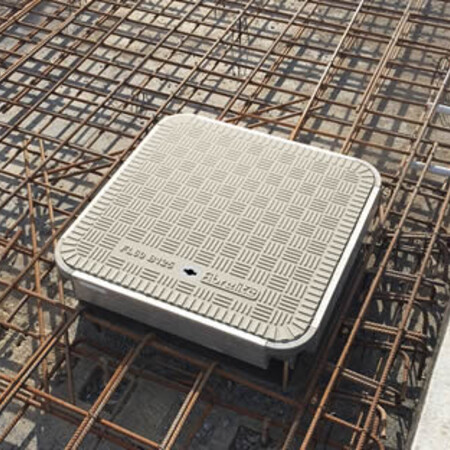

Engineered without compromise in the UK, US and Malaysia, Fibrelite is the global standard in Glass Reinforced Plastic (GRP) composite manhole covers, trench covers and underground enclosures.

Fibrelite is part of OPW and a sister company to Liquip.

Fibrelite design and engineer ultra-customisable solutions with an unrivalled strength-to-weight ratio, revolutionary lightness, reassuring safety and a proven reputation for performance.

View Our Categories

Innovative. Durable. Practical. Proven.

Relentless Pioneers in Composite Technology

Fibrelite was founded on two simple principles: uncompromising quality and endless innovation.

In 1980, we designed the world’s first composite manhole cover for Esso UK (ExxonMobil) – eliminating manual handling and any other health and safety issues associated with traditional metal covers.

Today, we remain at the cutting-edge of composite technology, pushing what’s possible, to fuel a new generation of maintenance-free products that meet the needs of clients across the globe.

Our ground-breaking F900 load rated trench cover and multiport sealed cover system are just two examples why, from airports, ports and energy, to retail and utilities, the future of GRP remains Fibrelite.

Sectors & Industries

Airport Maintenance Facility, UK

A third-party engineering and construction company contacted Fibrelite to provide a bespoke GRP composite trench covering arrangement to fit precast concrete service trenches at a UK airport maintenance facility.

Sphinx Airport, Egypt

Sphinx Airport is a new development located on the Cairo-Alexandria desert road near Giza City, Egypt. This airport will serve Grand Cairo as well as North Egypt and the delta.

Bremerhaven Harbour, Germany

Fibrelite’s German partner, KHK was approached for a refurbishment project on ship moorings in Bremerhaven harbour, Germany.

Major Northern Airport, UK

To meet the demands of an increasing population, this major airport in the North of England is undergoing major redevelopment.

Port of Immingham, UK

Ports are very busy areas, where safety and efficiency are key. There are constantly ships, trucks, cranes and many more vehicles moving around with heavy loads

Manchester Airport, UK

Fibrelite has recently supplied Manchester Airport 44 x FM45-80 trench covers (D400 load rating) with the encapsulating aluminium frame system

Leading Middle East Oil Company

In this case study, OPW is proud to show how their products (including the Fibrelite and KPS ranges) provided a leading Middle East oil company with a long-term underground containment and fuel transfer solution for their Qatar expansion programme

Shell Retail Fuelling, Eastfield, UK

When surveying Shell Eastfield as part of a refurbishment programme for the site, our UK site team discovered that two of the tanks had double manways that were too close together to install traditional tank sumps and required a bespoke solution work for a successful install.

BP, Family Farm, UK

OPW was approached by BP who required retrofit chamber systems which could be fitted to AdBlue dispensers at various petrol stations across the UK within a tight timeframe.

Oil Company, Malaysia

Fibrelite’s vacuum testable fibreglass tank sumps and dispenser sumps have been specified by a regional oil company in Malaysia

Z Energy Oil Company, Auckland, New Zealand

Fibrelite’s vacuum testable fibreglass tank sumps and 25 ton tonne rated composite covers have been specified by Z Energy Oil Company in New Zealand

BP, Auckland, New Zealand

BP New Zealand has standardised the use of Fibrelite tank sumps across its network. A BP connect site was upgraded with new tanks and Fibrelite’s S15CR-390 tank sump with manhole cover

Oil Refinery, North Killingholme, UK

A complex large-scale renovation project necessitating a carefully planned bespoke design.

Substation, Cowpen Bewley, UK

The health and safety issues associated with tired, cracked and crumbling concrete and bowed rusting steel covers have been instantly removed. All these hazards are eliminated with Fibrelite’s non-corrosive, non-cracking, slip resistant and incredibly strong trench panels

Natural Gas Substation, UK

Fibrelite’s range of covers offers easy access for operators at this Natural Gas processing site

Substation Rebuild, USA

Fibrelite’s HS-20 load rated composite trench covers have been selected by one of the nation’s largest metropolitan electrical utilities for a high-profile rebuild of a 345 kV bulk power substation

Cadent Gas, UK

Cadent Gas continue to roll out bespoke Fibrelite GRP composite trench access covers to their facilities across the UK to replace failing concrete infill covers, simplify access and increase H&S.

Power Station, Doncaster, UK

Electrical power generation facilities have large quantities of cabling running below the ground as a matter of course, which must be accessed regularly.

Airport Maintenance Facility, UK

A third-party engineering and construction company contacted Fibrelite to provide a bespoke GRP composite trench covering arrangement to fit precast concrete service trenches at a UK airport maintenance facility.

Nottingham City Hospital, UK

Hilton Bodill Construction contacted Fibrelite on behalf of their client, Nottingham City Hospital, who required a lightweight and strong modular covering system for their newly re-routed service trench, which replaced the traditional heavy concrete slabs.

Large Data Centre, Northern Europe

As demands for computing continues to significantly increase, and millions of people around the planet are online, the world’s data service providers need to continually expand their capacity to cope with the surge in demand.

Duke University, North Carolina

The trenches contained cables which ran from the power station at the top of the hill down to access points for vehicles including media trucks and vans, meaning that safe and easy access was essential.

Biopharmaceutical Plant, UK- Phase 2

Having supplied a retrofit solution to a previous service trench that was trafficked by HGV’s the customer approached Fibrelite to design a bespoke trench cover for this pedestrian traffic trench

London Zoo, UK

Fibrelite’s heavy duty composite trench covers have been specified for expansion work at a UK Zoo. The newly installed D400 trench panels are lightweight while maintaining the all-important strength properties of a 40 ton tonne load rated cover

Data Centre, Hong Kong

One of the largest data center centre developers and operators in Hong Kong S.A.R of China, came to Fibrelite looking for a retrofit replacement for their failing concrete trench access covers

Aerospace Facility, UK

Fibrelite’s range of standard and bespoke covers were designed and manufactured for this complicated application. The main requirement was easy access for operators who regularly need to enter these trenches that supply the manufacturing plant with essential services

Engine Manufacturing Facility, UK

Manufacturing plants require heavy-duty power cabling into the facilities to power their large amounts of machinery, especially in a highly technical industry like engine manufacture. The cables must be protected, yet easily accessible for inspection

Royal Canadian Mint, Winnipeg, Canada

Fibrelite designed and manufactured custom fiber reinforced plastic (FRP) (GRP) composite trench covers to fit directly into existing apertures

Pharmaceutical Facility, County Durham, UK

Fibrelite was approached by McLaughlin & Harvey to design and supply a custom trench access covering solution for a new build project in County Durham to accommodate a variety of trench widths, shapes and pipe and cable tray penetrations, required within a tight build schedule.

Large Data Centre, Northern Europe

As demands for computing continues to significantly increase, and millions of people around the planet are online, the world’s data service providers need to continually expand their capacity to cope with the surge in demand.

La Liga Stadium, Central Spain

Bespoke Fibrelite GRP trench covers were specified by a new La Liga stadium in central Spain to provide easy access to utilities (electric and water) in and around the stadium.

Premier League Stadium, UK- Phase 2

The composite trench covers were specified for the new and existing camera pits due to the manual handling issues experienced with the previously installed reinforced steel covers

Premier Multi-Event Stadium, UK

Years in the making, this was one of Fibrelite’s most complex projects yet. Hundreds of metres of custom trench access covers were custom engineered, and replaced failing covers around this prestigious stadium.

Leisure Centre, Sydney, Australia

As part of the renovation of Auburn City Council’s leisure centre, a simple access solution was required for access to the air conditioning system and balance tanks for the water set under around the perimeter of the pools

London Theatre, UK

The architects (Foster Wilson Architects LLP) who were project managing the refurbishment of the theatre tasked with providing a discreet and practical method of housing multicore cables that ran from the stage to the control desk during music concerts. Previously the cables had been run above ground

Leisure Centre, Keighley, UK

Fibrelite was recently commissioned to replace a corroded metal access cover pool side at a local leisure centre in Keighley

Educational Facility Grease Pits, UK

A solution was needed to solve the problems caused by the previously installed galvanised covers used to cover a 2800 x 1400mm grease pit. These covers claimed to be odour tight but weren’t, resulting in the constant emission of a terrible odour. The heavy galvanised covers were also extremely difficult to

Rail, Darlington, UK

As part of a platform upgrade programme, Colt Construction (Principle Contractors) approached Fibrelite looking to replace and colour match Darlington railway stations broken and damaged recessed covers

Premier League Stadium, UK- Phase 2

The composite trench covers were specified for the new and existing camera pits due to the manual handling issues experienced with the previously installed reinforced steel covers

Rail Maintenance Facility, Doncaster, UK

This Doncaster rail maintenance facility required custom-made trench covers to accommodate a selection of different sized piping which need to run vertically through the covers and into the trenches

Nottingham Tramline, UK

Fibrelite developed a completely bespoke cover and frame for this complicated application. The main requirement was easy access for operators who regularly need to enter these feeder chambers that supply the overhead lines to power the trams

Newcastle Train Station, UK

Fibrelite has recently developed a range of bespoke, lightweight, composite trench covers, dramatically reducing the cost to cover larger openings. These bespoke covers have recently been installed over access hatches in the platform of a major UK rail station

Railway Maintenance Depot, London, UK

Fibrelite’s bespoke lightweight composite trench covers have recently been installed over a service trench at the primary railway maintenance depot for the Docklands Light Railway. These were installed to give quick and easy access to the service trench

Access Pits, Kuala Lumpur, Malaysia

Water mains in cities are traditionally run under roads to allow for maintenance. At regular intervals along the pipes, valves are located to regulate or shut off water flow in the event of a leak or other necessary work. Valves are set in access pits in the road (often the middle or side) under access […]

Hammersmith Flyover Bearing Pits, London, UK

As part of the essential refurbishment and strengthening of this iconic London flyover, roller bearings at the base of the supporting piers were replaced due to wear, corrosion and the ever increasing vehicular traffic volume

Center of Disease Control, Atlanta, USA

An Atlanta based engineering firm asked Fibrelite to solve a problem for the CDC location in Atlanta Ga. The facility has a new diesel fueling facility where vehicles are fueled. They wanted to have easy access to their overspill vault set across the street from the loading facility

Tunnel Project, Germany

Fibrelite’s lightweight composite covers have been used to replace old concrete covers that had become unsafe, and unfit for purpose. The FL60-D400 covers were installed as a replacement to the previous concrete ones

M4 East Bound, Newport, UK

Fibrelite’s range of covers offers easy access for operators who regularly need to access these chambers that house communication cables and CCTV camera cables

Turnpike Authority, USA

Fibrelite’s lightweight FRP GRP manhole covers were identified by an engineering consultant working for this particular Turnpike Authority

Innsbrucker Kommunale, Austria

Fibrelite provided a lightweight replacement for previously installed heavy (15cm thick) concrete/steel infill covers at an intersection in the center of Innsbruck, Austria.

Duke University, North Carolina

The trenches contained cables which ran from the power station at the top of the hill down to access points for vehicles including media trucks and vans, meaning that safe and easy access was essential.

JOD Engineering, Bolton, UK

JOD Engineering Services LTD approached Fibrelite looking for a lightweight covering solution to replace their existing heavy covers, the client supplies fresh water to millions of homes across the North West of England.

Water Company, Connecticut, USA

In 2017, in conjunction with an effort to automate their water meter collection services, this water company contacted Fibrelite about the possibility of installing automatic water meter readers in or beneath a composite cover

Flood Alleviation Scheme, UK

As part of the current AMP5 programme, a flood alleviation scheme required Fibrelite’s range of standard covers to be designed and manufactured for this complicated application

Waste Water Plant, Antarctic

This specialist piece of equipment that has been designed and manufactured for use in the Antarctic required lightweight covers for easy access. Fibrelite’s range of standard trench covers was identified as the solution and became an integral part of the design

Financial Centre, Singapore

One of Japan’s largest general contractors, a global leader in civil engineering, construction and development projects has specified Fibrelite’s lightweight non-corrosive composite access covers for a new financial centre development in Singapore

Berjaya Times Square, Malaysia

A major Malaysian utility company contacted Fibrelite Asia for advice on a specific set of issues it was experiencing with an existing installation

District Energy Provider, Minneapolis, USA

As part of a refurbishment program to replace/re-lag steam lines in Minneapolis a leading district energy provider has chosen Fibrelite’s FRP GRP composite steam trench panels to replace aluminium vault covers in the sidewalk

District Energy Provider, Boston, USA

A leading owner/operator of district energy networks in the US has chosen Fibrelite’s composite steam covers to replace cast iron manhole covers in the sidewalk

Fire Water Tanks, California, USA

A California business development required easy and quick access to their fire water manway tanks in case of emergency. They chose Fibrelite’s H20 rated trench lids which can be manually lifted so heavy machinery is not required

Read more

Hospital, UK

Fibrelite’s lightweight anti-slip composite FM45 trench panels have recently been specified to replace over 33 metres of crumbling, hard to remove concrete panels

Indiana University, Bloomington

The previously installed metal covers made access difficult, the adverse conditions of steam vaults had caused the locking mechanisms to fail. The covers would heat up due to the steam vaults below, creating a health and safety hazard and putting the students and maintenance staff at risk of burning themselves.

District Energy Provider, Minneapolis, USA

As part of a refurbishment program to replace/re-lag steam lines in Minneapolis a leading district energy provider has chosen Fibrelite’s FRP GRP composite steam trench panels to replace aluminium vault covers in the sidewalk

Leading US Northeastern University, Boston, USA

This leading University’s engineering and utility project management team first learned about Fibrelite’s composite steam manhole covers at an International District Energy Association (IDEA) conference several years ago

Leading University, Cambridge, USA

A top ranking university in Cambridge, MA, has recently turned to Fibrelite for the replacement of steam manhole covers within the Business School campus

Public Liberal Arts University, Willimantic, USA

One of the oldest universities in Connecticut has recently begun a replacement program for their existing utilities manhole covers. The university turned to Fibrelite to provide a solution that eliminated the occupational injury risks associated with the removal of heavy, cast iron manhole covers

University of Florida, USA

A top state university in Gainesville, Florida, has recently turned to Fibrelite for the replacement of 24” steam manhole covers on campus. The university had decided to seek an alternative to their existing covers due to their concerns regarding public and staff safety

Trinity Shopping Centre, Leeds, UK

190 Fibrelite trench covers are now installed in the state of the art Trinity Shopping Centre in Leeds. The consulting engineers specified Fibrelite for this project for ease of access to cable ducts that run all over the site

Leeds Market, UK

A local UK council has specified Fibrelite FM45 trench panels for a busy city-centre market.